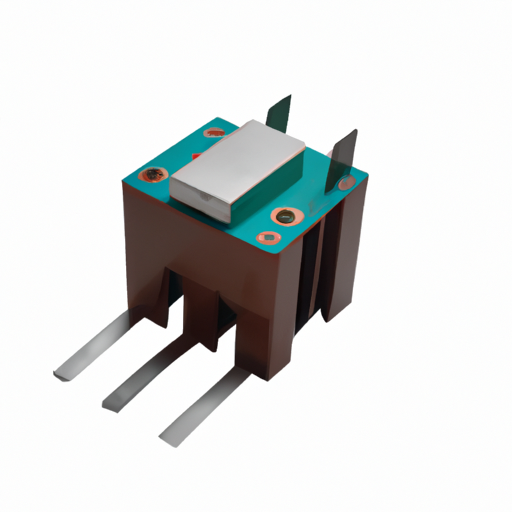

CFR-50JB-52-1M6 Isolation Transformers and Autotransformers: Core Functional Technologies and Application Development Cases

Isolation transformers and autotransformers are essential components in electrical systems, providing critical functions in power distribution, voltage regulation, and safety. The CFR-50JB-52-1M6 model serves as a prime example of the advancements in transformer technology. Below, we delve into the core functional technologies, applications, and development cases for both types of transformers.

Core Functional Technologies

Isolation Transformers 1. **Electromagnetic Induction**: Isolation transformers operate on the principle of electromagnetic induction, where the primary and secondary windings are magnetically coupled but electrically isolated. This design ensures that any faults in the secondary circuit do not affect the primary circuit.

2. Voltage Regulation: These transformers can step up or step down voltage levels while maintaining electrical isolation, which is crucial for protecting sensitive electronic equipment from voltage fluctuations.

3. Safety Features: By isolating the load from the power source, isolation transformers enhance safety by reducing the risk of electrical shocks and minimizing ground loop issues.

4. Noise Filtering: Isolation transformers are effective in filtering out electrical noise, making them ideal for applications involving sensitive electronic devices, such as audio and medical equipment.

Autotransformers 1. **Single Winding Design**: Autotransformers utilize a single winding that serves as both the primary and secondary winding. This design allows for a more compact and efficient transformer compared to isolation transformers.

2. Voltage Adjustment: They can step up or step down voltage levels with less material, resulting in a lighter and more cost-effective solution.

3. Higher Efficiency: Autotransformers generally exhibit higher efficiency due to reduced copper and iron losses in the winding, making them suitable for applications where efficiency is paramount.

4. Non-Isolated Applications: Autotransformers are commonly used in scenarios where electrical isolation is not critical, such as in motor starting and voltage regulation.

Application Development Cases

Isolation Transformers 1. **Medical Equipment**: In healthcare settings, isolation transformers are crucial for powering medical devices, ensuring patient safety by isolating sensitive equipment from the mains supply. This is particularly important in environments where patient safety is paramount.

2. Industrial Automation: Isolation transformers are employed in control panels to protect sensitive control circuits from voltage spikes and transients, ensuring reliable operation of automated systems.

3. Data Centers: In data centers, isolation transformers help reduce electrical noise and provide a stable power supply to servers and networking equipment, enhancing performance and reliability.

4. Audio Equipment: High-fidelity audio systems often incorporate isolation transformers to eliminate ground loops and improve sound quality, ensuring a clean audio signal.

Autotransformers 1. **Motor Starting**: Autotransformers are widely used in starting large motors, providing reduced voltage to limit inrush current during startup, which helps prevent damage to the motor and associated equipment.

2. Voltage Regulation in Power Distribution: In substations, autotransformers are utilized to adjust voltage levels for efficient power distribution, ensuring that voltage remains within acceptable limits for end-users.

3. Railway Systems: Autotransformers are employed in railway electrification systems to step down high voltage for train operations, facilitating efficient and safe transportation.

4. Renewable Energy Systems: In solar power systems, autotransformers can be used to match the output voltage of solar inverters to the grid voltage, optimizing energy transfer and integration with the power grid.

Conclusion

Isolation transformers and autotransformers are integral to modern electrical systems, each serving distinct yet complementary roles. The CFR-50JB-52-1M6 model exemplifies the advancements in transformer technology, offering effective solutions for a wide range of applications, from industrial automation to renewable energy systems. Understanding the core functionalities and applications of these transformers enables engineers and designers to make informed decisions when integrating them into their systems, ultimately enhancing performance, safety, and efficiency.